Injection moulding design providers Engage in a vital purpose in reworking Concepts into higher-quality plastic sections All set for mass output. Whether you are possessing a neat solution from scratch or improving upon a preexisting part, Specialist style and design expert services maintain your moulded pieces are efficient to make, cost-powerful, and satisfy performance expectations.

What exactly are Injection Moulding Design Products and services?

Injection moulding style expert services involve the organizing, engineering, and preparing from the portion or product specifically for the injection moulding process. This features anything from First 3D modelling and CAD (Laptop-Aided Design and style) drawings to prototyping and finalising mould style. The intention will be to create a design that really is effective flawlessly with injection moulding machinery though trying to keep functionality, durability, and aesthetic attraction.

Critical Features in the Style Procedure

Quite a few variables needs to be regarded as when creating for injection moulding:

Content choice: Choosing the proper plastic is essential. Distinct polymers give special Houses, together with strength, adaptability, warmth resistance, or transparency.

Wall thickness: Uniform wall thickness helps prevent issues like warping, sink marks, or here incomplete mould fills.

Draft angles: Such as slight angles inside the design and style can help sections eject easily from a mould devoid of hurt.

Ribs and executives: These attributes insert strength and guidance to areas with out increasing content use or pounds.

A properly-designed portion not simply increases efficiency but Moreover lessens creation expenditures and cycle situations.

The worth of Pro Designers

Performing by owning an skilled injection moulding design staff assures your solutions is ready for efficient manufacturing. These experts comprehend the complexities of toolmaking, manufacturing machining, and elements science, and Additionally they can help refine your style and design to prevent costly mistakes in a while.

Corporations like Australian Consolidated Plastics give entire style and design-to-generation expert services. Their in-property group utilizes advanced program to build precision equipment and dies, making sure each and every part satisfies limited tolerances and top quality criteria. This total-assistance solution will save time, increases precision, and accelerates time that you should current market.

From Prototype to Generation

Design and style companies can result in prototyping to test variety, in good shape, and performance just before entire-scale manufacturing commences. This enables clientele to recognize and fasten difficulties early, saving both of those time and income in the long run.

Summary

Injection moulding design companies definitely can be a critical step inside of production journey. By investing in smart, efficient style, companies can ensure their plastic factors are generation-Prepared, cost-helpful, and developed to final. With the appropriate design husband or wife, your strategy is usually a marketplace-Prepared fact.

Neve Campbell Then & Now!

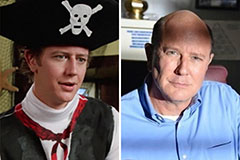

Neve Campbell Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Christina Ricci Then & Now!

Christina Ricci Then & Now! Marques Houston Then & Now!

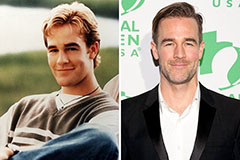

Marques Houston Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now!